Druckbehälter, Fässer, Fasstrichter & Sonderkonstruktionen aus Edelstahl für Pharma, Kosmetik & Feinchemie, die neue Standards setzen

Qualität & Sicherheit erhöhen durch minimale Partikelanhaftung

- Kontaminationsfreie Produktion: Edelstahloberflächen von BOLZ INTEC sind optimiert für Branchen mit den höchsten Ansprüchen an Hygiene & Reinheit.

- Reproduzierbare Produktqualität: Edelstahloberflächen von BOLZ INTEC sind makellos und reduzieren die Gefahr von Produktionsausfällen & Produktrückrufen.

- Einhaltung höchster Standards: Edelstahloberflächen von BOLZ INTEC gewährleisten die Einhaltung der Standards von GMP und EHEDG.

Über 2.000 Kunden in 48 Ländern vertrauen in unsere Behälter, Fässer & Apparate aus Edelstahl

BOLZ INTEC steht für Innovation, Qualität und Präzision in der Herstellung von Edelstahlfässern, Druckbehältern, Apparaten und Sonderkonstruktionen nach den Anforderungen unserer Kunden. Als langjähriger Partner der Pharma-, Spezialchemie- und Kosmetikindustrie schaffen wir Lösungen, die Maßstäbe bei Qualität und Hygiene setzen, die unseren Kunden entscheidende wirtschaftliche Vorteile bringen und die die Sicherheit von Produkt und Produktion erhöhen.

Unsere Edelstahlbehälter und Sonderkonstruktionen werden nach GMP und EHEDG Hygienic Design Richtlinien gefertigt. Sie sind prädestiniert für den Einsatz in hygienesensiblen Umgebungen. Die praxisnahe Produktentwicklung von BOLZ INTEC gewährleistet ihre kompromisslose Qualität und Sicherheit.

15 der 20 größten Pharmaunternehmen weltweit sind Kunden von BOLZ INTEC

15 der 20 größten Pharmaunternehmen weltweit zählen zu den Kunden von BOLZ INTEC

Marktkapitalisierung Top 20 Pharmaunternehmen 2022, Quelle: GlobalData

Kunden aus diesen Branchen erhöhen ihre Effizienz mit Behältern, Apparaten & Konstruktionen aus Edelstahl von BOLZ INTEC

Produktportfolio von BOLZ INTEC

Druckbehälter

Edelstahlfässer

Trichter & Sondertrichter

Sonderkonstruktionen

Das Optimized Grind Finishing-Verfahren (OGF)

In der Pharmazie, Chemie und Lebensmittelverarbeitung ist die Minimierung von Anhaftungen in Behältern ein kritischer Faktor für Effizienz und Qualität. Die Anhaftung von Substanzen an den Innenwänden von Behältern kann zu erhöhtem Reinigungsaufwand, Produktverlusten und Kontaminationen führen. Das kostet Geld und bindet Ressourcen. Vor allem in Branchen, in denen die Zertifizierung nach EHEDG (European Hygienic Engineering & Design Group) und Hygienic Design an Bedeutung gewinnen, ist die Anhaftungsminimierung zu einem kritischen Faktor geworden.

Die Forschung von BOLZ INTEC in Kooperation mit der Hochschule Konstanz hat ergeben, dass die Art und Weise, wie Edelstahloberflächen abgetragen werden, eine Schlüsselrolle für die Minimierung der Anhaftung spielen. Unterschiedliche Schleifmethoden ergeben, trotz gleicher Ra-Werte, unterschiedliche Anhaftverhalten und das OGF-Verfahren von BOLZ INTEC führt zu einer geringeren Anhaftung von Partikeln.

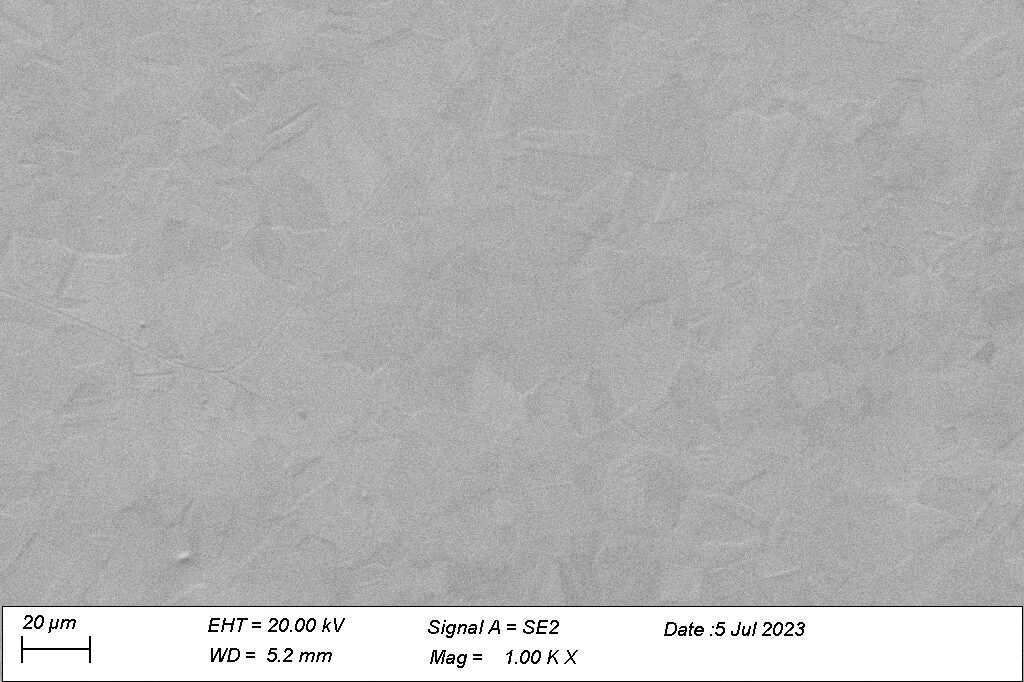

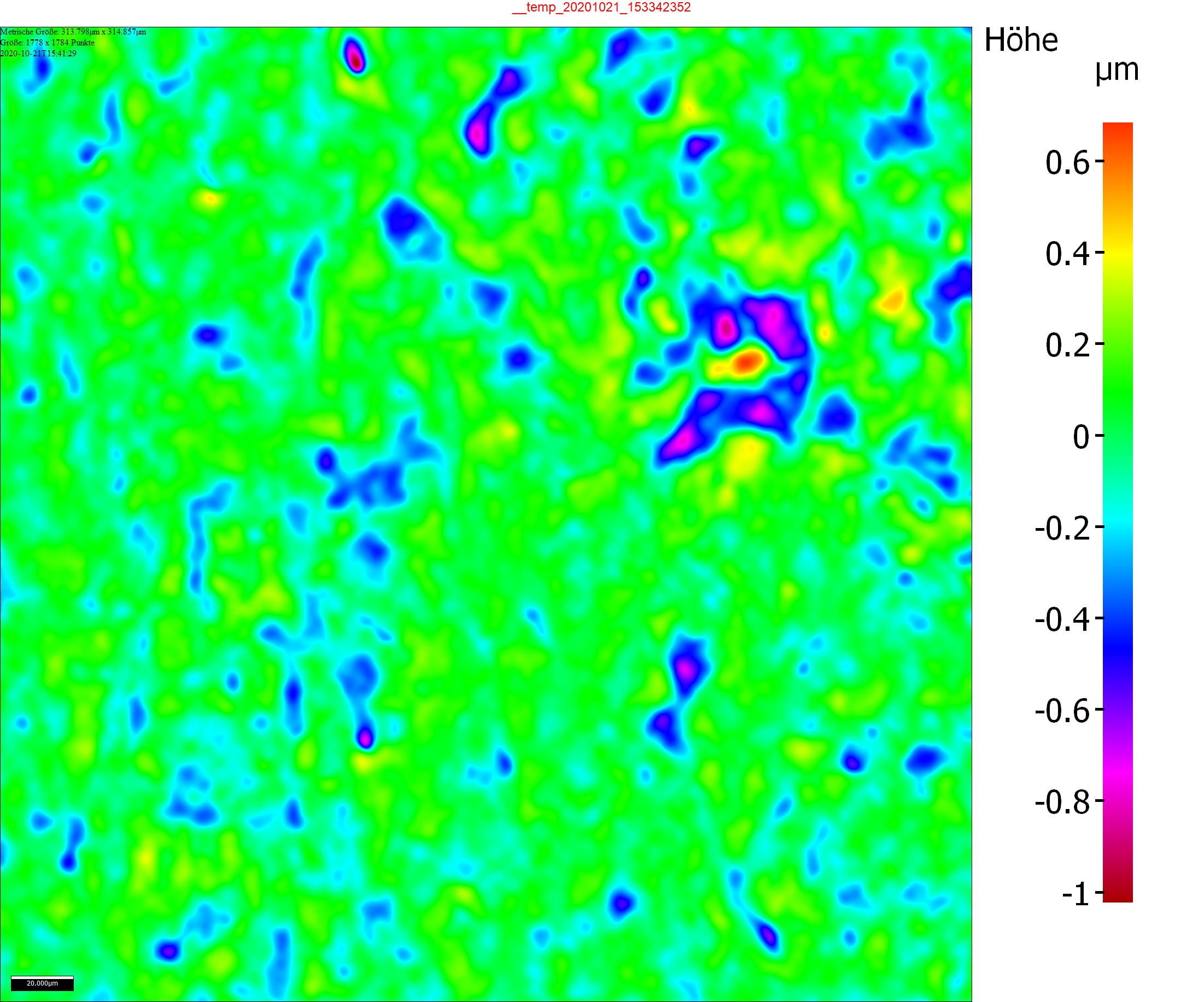

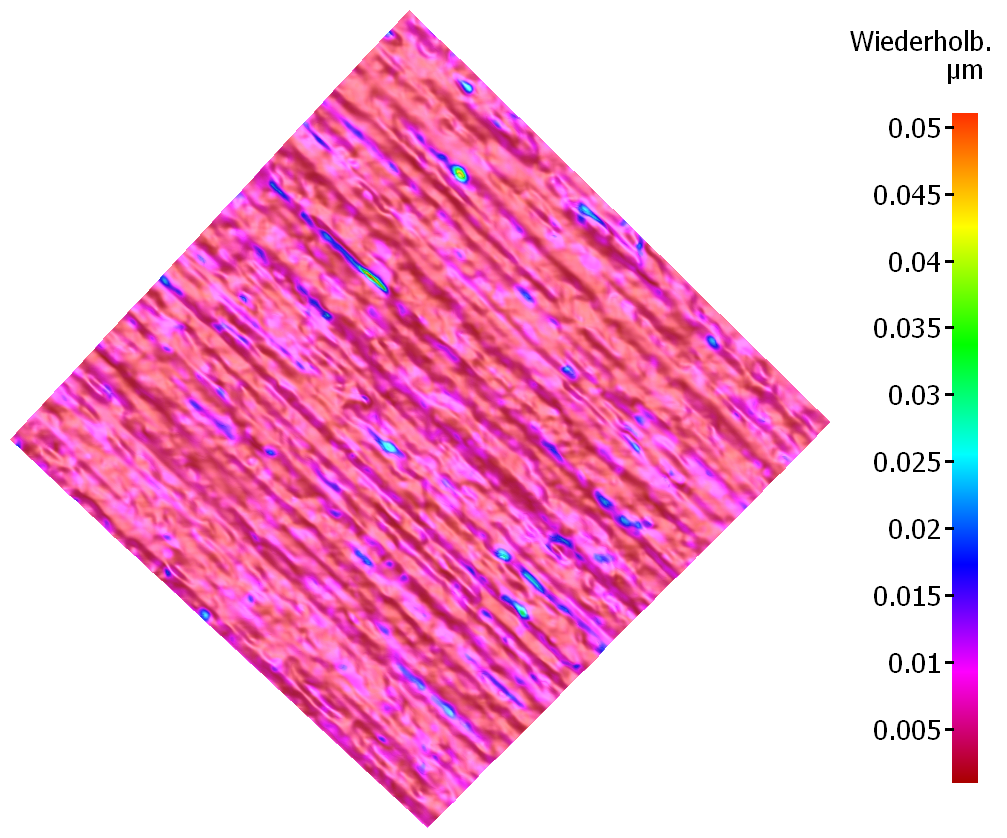

Nachfolgend eine Aufnahme per Rasterelektronenmikroskop der Edelstahloberfläche nach Elektropolieren und Optimized Grind Finishing, sowie Abbildungen der Flächentextur-Rauheitsdaten und zur Wiederholbarkeit.

Leichte Reinigung & minimale Anhaftung

Das Optimized Grind Finishing (OGF)-Verfahren führt zu einer geringen Anhaftung von Partikeln auf den Oberflächen der Behälter. Dies verbessert die Reinigungseffizienz erheblich und reduziert das Risiko der Kontamination von Produktchargen.

Reproduzierbare Qualität der Oberflächen

Das OGF-Verfahren ermöglicht eine reproduzierbare Qualität der Oberflächen. Im Gegensatz zu herkömmlichen Verfahren, bei denen variable Faktoren wie manueller Anpressdruck oder Qualität von Schleifmitteln eine Rolle spielen, bietet das OGF-Verfahren eine gleichbleibende Qualität der Oberflächen.

Optische Ästhetik und geringe Fehleranzahl

Die mit dem OGF-Verfahren behandelten Edelstahloberflächen weisen eine ansprechende optische Ästhetik auf und Fehler in der Oberflächenstruktur werden aufgrund des feinen und schonenden Abtragprozesses deutlich reduziert. Dies ist besonders wichtig in Branchen, die hohe Anforderungen an die Sicherheit stellen.

Verbesserter Korrosionsschutz

Durch das Elektropolitur-Verfahren wird nicht nur die optische Qualität verbessert, sondern es treten auch chemische Veränderungen auf, die zu einem verbesserten Korrosionsschutz führen. Dies ist besonders relevant für Anwendungen in chemischen und pharmazeutischen Prozessen.

Reduziertes Risiko der Chargenkontamination

Die Verbesserung des Reinigungsverhaltens durch das OGF-Verfahren führt zu einer starken Verringerung der Restschmutzanhaftung in den Behältern. Dadurch wird das Risiko einer Kontamination zwischen verschiedenen Produktchargen deutlich reduziert.

Anwendbarkeit in kritischen Branchen

Das Verfahren wird als besonders vorteilhaft für kritische Branchen wie die Nanotechnologie oder die Bio- und Pharmatechnologie angesehen, in denen höchste Reinheitsansprüche und die Vermeidung von Kontaminationen von entscheidender Bedeutung sind.

Effizienzsteigerung durch minimale Anhaftung

Einfach E-Mail absenden und Download-Link erhalten

Dienstleistungen von BOLZ INTEC

Technische Beratung & Konstruktion

Fass-Instandsetzung

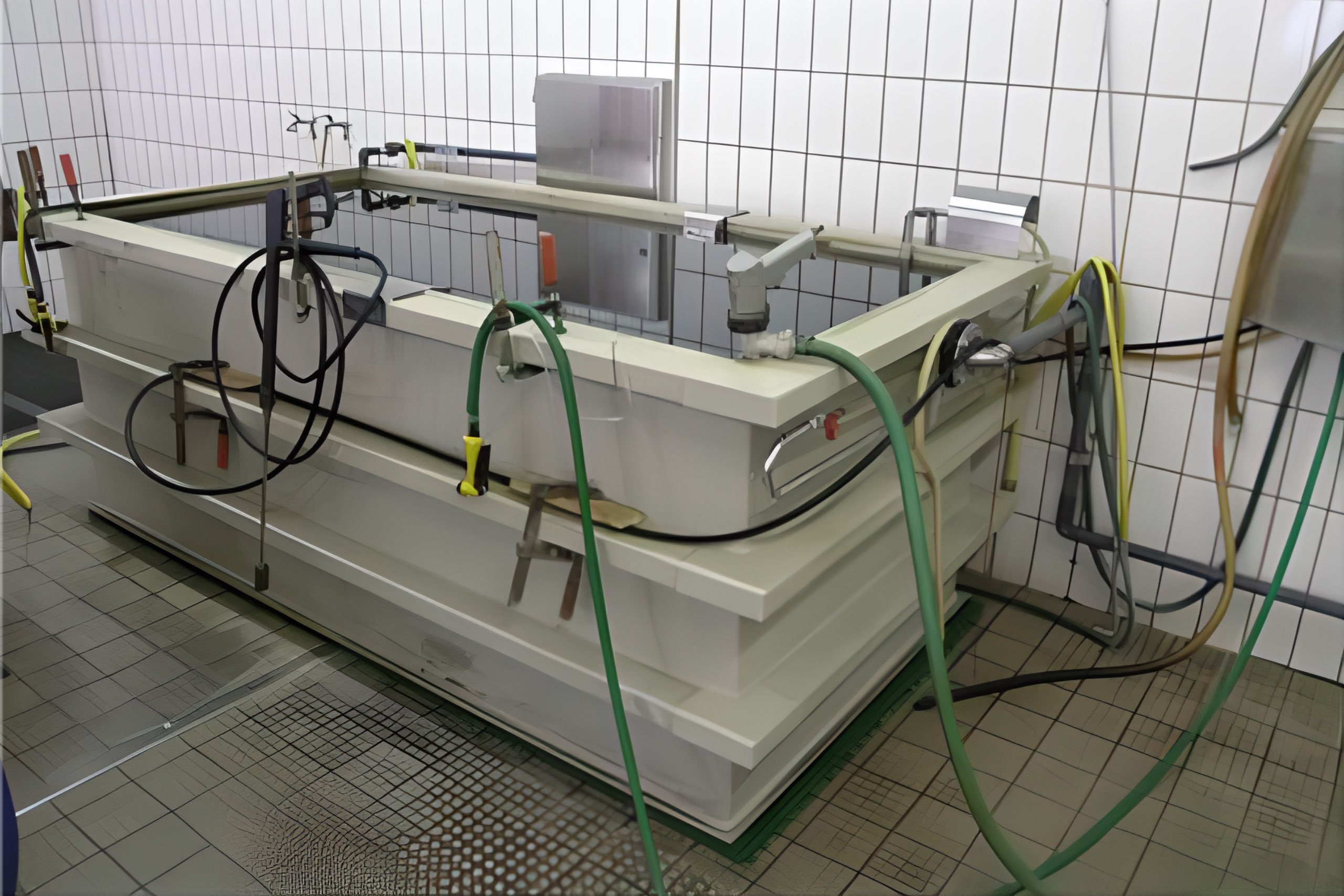

Simoflex® Fasswäsche

Elektropolieren

Warum sich Kunden weltweit für unsere Behälter aus Edelstahl entscheiden

Tradition & Innovation seit 1919

BOLZ INTEC ist der Spezialist für die Anfertigung von Edelstahlfässern, Druckbehältern, Rührwerksbehältern, Transportbehältern und Transfersystemen für hygienesensible Branchen.

Hohe Wertschöpfungstiefe

BOLZ INTEC hat sich ausgesprochene Expertise in der Bearbeitung nichtrostender Edelstähle und Sonderwerkstoffe, wie Hastelloy, angeeignet. Kombiniert mit den Fähigkeiten und Fertigkeiten unseres Teams, ermöglicht dies ein Höchstmaß an Fertigungstiefe. Sämtliche Produktionsschritte werden im Haus vollzogen. Deshalb ist BOLZ INTEC in der Lage, überaus flexibel auf Lieferterminwünsche von Kunden zu reagieren und einzigartige Qualität zu gewährleisten.

Kundenspezifische Lösungen

Unsere Konstruktion konzipiert, plant und entwickelt praxisnah Produkte nach den Anforderungen unserer Kunden. Dazu gehören z.B. Behälter für pastöse Stoffe oder Flüssigkeiten, Transportbehälter für UN-Gefahrgüter, Kannen zur Lagerung und zum Transfer von Wirkstoffen, Absaughauben zur staubfreien Containerbeschickung und vieles mehr.

Einzelanfertigung & Kleinserien

BOLZ INTEC fertigt auch Einzelanfertigungen und Kleinserien.

Maschinen für perfekte Oberflächen

Im Maschinenpark von BOLZ INTEC ist nichts von der Stange. Von der Tiefziehpresse bis hin zur Elektropolieranlage, arbeiten wir mit Spezialmaschinen, die nach unseren eigenen Spezifikationen entstanden sind, um höchste Ansprüche an Qualität und Präzision zu erfüllen.

Rückverfolgbarkeit & Reproduzierbarkeit

Das QM-System von BOLZ INTEC und unsere intensiven Prüfverfahren sichern die konsistente Qualität der von BOLZ INTEC gefertigten Edelstahloberflächen. Damit leisten wir einen entscheidenden Beitrag für die Rückverfolgbarkeit von Produkten in kritischen Branchen.

Vertrauen & Sicherheit

Unser Streben nach perfekter Qualität, modernste Fertigungsmethoden, aber auch handwerkliches Können und Know-how sind die Grundlage für die überlegene BOLZ INTEC Qualität, die Sicherheit und Zuverlässigkeit für unsere Kunden bedeutet. So ist es nicht verwunderlich, dass 80% unserer Kunden in den letzten 10 Jahren jährlich nachbestellt haben.

Umfangreiche Zertifizierung

Unsere Qualität lassen wir uns regelmäßig extern zertifizieren: DIN 9001:2015, DIN EN ISO 3834-2:2006-03, DIN EN ISO 115085-2/CL1. Wir sind Fachbetrieb nach WHG §19/1 und führen Verfahrensprüfungen nach DIN EN ISO 15614-1, Bedienerprüfungen nach DIN EN 1418 durch. BOLZ INTEC erfüllt die Druckgeräterichtlinie-2014-68-EU/AD-2000 HPO und beschäftigt Intern. Schweißfachingenieure (DVS/IIW 1170).

Hohe Effizienz, niedrige Kosten & große Wirtschaftlichkeit durch überlegene Edelstahloberflächen

Zeitersparnis in der Produktion

Die Verwendung von Edelstahlbehältern mit optimierten Oberflächen führt zu einer signifikanten Zeitersparnis im Produktionsprozess. Durch die Minimierung der Anhaftung von Materialien können Reinigungs- und Wartungszeiten drastisch reduziert werden. Dies ermöglicht eine schnellere Wiederverwendung der Behälter und erhöht die Gesamteffizienz der Produktionslinien. In einem produktionsintensiven Umfeld, wo Zeit gleichbedeutend mit Geld ist, stellt diese Zeitersparnis einen erheblichen wirtschaftlichen Vorteil dar.

Geringeres Risiko von Produktionsausfällen

Die reproduzierbare Qualität der Edelstahloberflächen und die reduzierte Fehleranzahl minimieren das Risiko von Produktionsausfällen aufgrund von Oberflächenproblemen. Dies kann zu einer höheren Gesamtproduktivität und geringeren Ausfallzeiten führen.

Verringerung von Produktionsverlusten

Durch die Optimierung der Behälteroberflächen wird zudem die Menge an Produktverlusten minimiert. Geringere Anhaftung bedeutet, dass mehr produziertes Material für den eigentlichen Verwendungszweck zur Verfügung steht und nicht als Abfall endet. Das ist ein besonders wichtiger Faktor in Branchen, in denen hochwertige oder sehr kostspielige Materialien verarbeitet werden.

Verbesserung von Produktqualität & Produktsicherheit

Eine kontaminationsfreie Produktion resultiert in einer höheren Qualität des Endprodukts. Dies ist entscheidend in Branchen mit strengen Qualitäts- und Reinheitsanforderungen, wie der Pharmazie und Lebensmittelherstellung, wo Reinheit und Sicherheit oberste Priorität haben. Die Verwendung von optimierten Edelstahlbehältern kann daher auch zu einer Verbesserung des Markenimages und der Kundenzufriedenheit führen.

Kosteneinsparungen durch effizientere Reinigung

Neben der Zeitersparnis führen optimierte Oberflächen auch zu einer Reduzierung der Kosten für Reinigungsprozesse. Weniger Anhaftungen bedeuten einen geringeren Bedarf an Reinigungsmitteln, Wasser und Energie. Außerdem reduziert sich der Verschleiß an den Behältern selbst, was die Lebensdauer erhöht und die Notwendigkeit für Neubeschaffungen verringert. Langfristig gesehen können diese Einsparungen bei den Betriebskosten einen bedeutenden Unterschied in der Profitabilität eines Unternehmens ausmachen.

Längere Lebensdauer der Behälter

Der verbesserte Korrosionsschutz durch das Elektropolitur-Verfahren trägt dazu bei, die Lebensdauer der Edelstahlbehälter zu verlängern. Kunden können dadurch ihre Kosten für Ersatzinvestitionen und Wartung reduzieren.

In wenigen Schritten zum Ziel

Anfrage

Senden Sie uns eine E-Mail, rufen Sie uns an oder buchen Sie einen Termin über Calendly. Im Telefonat mit einem unserer kompetenten Ansprechpartner klären wir vorab einige Fragen anhand von Checklisten und senden Ihnen eine Geheimhaltungsvereinbarung (NDA).

Testphase

Auf Basis Ihrer Ziele und Spezifikationen erhalten Sie aus unserem Testcenter - je nach Bedarf - Fässer, Behälter, Trichter und Zubehör zum Ausprobieren und Testen. Mit Ihrem Testequipment können Sie die Spezifikationen Ihrer Anfrage verifizieren oder anpassen.

Angebot

Im Rahmen eines Besuchs bei Ihnen vor Ort beraten unsere kompetenten Ansprechpartner Sie bei der Klärung letzter Fragen, bei der Lösungsfindung für erkannte Probleme und bei der exakten Bedarfsdefinition. Im Anschluss können wir mit der Fertigung starten.

letzte Woche ist das letzte Fass bei uns eingetroffen. Alle Teile gemäß Auftrag haben wir damit zeitgerecht erhalten. Ihre zeitnahe und fachlich fundierte Unterstützung hat es uns ermöglicht, unsere Zeitpläne einzuhalten. Für die konstruktive, professionelle und zuverlässige Zusammenarbeit möchte ich mich abschließend bedanken.“

der Kunde hat den Trichter abgenommen und ist super zufrieden.

Ich wollte mich noch mal für die schnelle Bearbeitung und Lieferung bedanken...“

herzlichen Dank für diese gute Nachricht und bitte richten Sie Ihren Mitarbeitern in der Fertigung und allen, die damit zu tun hatten, ebenfalls unseren Dank aus, da es nun doch noch geklappt hat, für uns die Tanks recht kurzfristig zu fertigen. Damit haben Sie uns sehr geholfen.“

Unser Projektteam freut sich auf Ihre Anfrage

Sie haben Fragen zu unseren Produkten und Leistungen oder möchten von einem unserer kompetenten Mitarbeiter beraten werden?

Rufen Sie un an oder schreiben Sie uns eine E-Mail. Wir nehmen uns Zeit für Sie und rufen auf Wunsch auch gerne zurück.

Interessantess & Wissenswertes

1919

ist das Jahr der Gründung von BOLZ INTEC

49

top-qualifizierte und Mitarbeiterinnen & Mitarbeiter mit einer Leidenschaft für Qualität hat BOLZ INTEC

0,5

Liter fasst das kleinste Fass der Welt von BOLZ INTEC mit den Dimensionen Ø120 V0,5l

20

Jahre Lebensdauer hat ein Edelstahlfass von BOLZ INTEC bei regelmäßiger Instandhaltung

3

mal schneller ist die Fließgeschwindigkeit viskoser Medien in einem Fass von BOLZ INTEC mit OGF-Veredelung

4

ist der Faktor der Zeitersparnis bei der Reinigung von Edelstahlfässern mit Veredelung durch das OGF-Verfahren von BOLZ INTEC

4

mal schneller fließt Hyaluronsäure in einem Behälter von BOLZ INTEC, dessen Oberfläche OGF-veredelt wurde

1963

startete BOLZ INTEC mit der Produktion von runden Behältern aus Edelstahl

3.500

m2 ist die Produktionsfläche von BOLZ INTEC

12

bar ist der maximale Druck bei Druckbehältern von BOLZ INTEC

500

Liter fasst das größte Fass von BOLZ INTEC

0,05

Ra < 0,05 µm ist die Rauheit von Edelstahloberflächen, die mit dem OGF-Verfahren von BOLZ INTEC veredelt wurden

News / Presseartikel / Termine / Messen

Prof. Dr.-Ing. Arnulf Hörtnagl, Vortrag PharmaTechnica 2024

Ferry Boat 2024

ACHEMA 2024

Werden Sie unser Entwicklungspartner oder Vertriebspartner!

Bringen Sie Ihr Fachwissen und Ihre ganze Erfahrung ein, um gemeinsame Ziele zu erreichen und innovative Ideen zu verwirklichen.

- Entwickeln und gestalten Sie in enger Zusammenarbeit mit BOLZ INTEC branchenführende Produkte, Services und Projekte.

- Bieten Sie die innovativen und umsatzstarken Produkte und Leistungen von BOLZ INTEC auf Ihrem Markt, in Ihrer Branche und bei Ihren Kunden an.

Sie fragen, wir antworten

Unsere Edelstahlbehälter und Apparate finden in verschiedenen Branchen Anwendung, darunter Pharma, Chemie, Lebensmittel, Kosmetik, Energie- und Umwelttechnik, Luft- und Raumfahrt, sowie Forschungseinrichtungen und Labore.

Unsere Edelstahlbehälter sind in einer Vielzahl von Größen und Kapazitäten erhältlich, um den individuellen Anforderungen unserer Kunden gerecht zu werden. Kontaktieren Sie uns für maßgeschneiderte Lösungen.

Wir bieten kundenspezifische Lösungen und passen unsere Edelstahlbehälter an individuelle Anforderungen, wie Prozessparameter, Volumen und spezielle Funktionen an.

Unsere Dienstleistungen umfassen Elektropolitur, mechanische Bearbeitung und das einzigartige Optimized Grind Finishing (OGF)-Verfahren für optimale Oberflächenqualität und minimale Partikelanhaftung.

Unsere Behälter erfüllen die strengen Hygienestandards der EHEDG (European Hygienic Engineering & Design Group) und sind somit ideal für den Einsatz in hygienesensiblen Branchen.

Unser erfahrenes Team bietet umfassende Beratung und Unterstützung bei der nahtlosen Integration unserer Edelstahlbehälter und Apparate in bestehende Produktionsprozesse.

Der Wartungsaufwand für unsere Edelstahlbehälter und Apparate ist minimal. Regelmäßige Inspektionen und gegebenenfalls Reinigungen sind ausreichend. Unsere Edelstahlbehälter sind langlebig und robust und im Falle des Falles bieten wir unseren Kunden deren Instandsetzung an.

Unsere optimierten Edelstahlbehälter bieten bessere Reinigungseigenschaften, geringere Partikelanhaftung und entsprechen den höchsten Hygiene- und Reinheitsstandards.

Unsere Edelstahlbehälter sind widerstandsfähig gegenüber aggressiven Chemikalien und eignen sich perfekt für sichere Lagerung und Transporte in der chemischen Industrie.

Die Oberflächenbeschaffenheit beeinflusst maßgebend die chemischen und physikalischen Eigenschaften von Edelstählen. In hygienesensiblen Branchen, wie der Pharma-, Kosmetik- und Lebensmittelindustrie gewinnen Fachbegriffe wie EHDG oder auch das Hygienic design immer mehr an Bedeutung. Hintergrund ist, dass Betreiber eine Verschleppung von Partikeln und die somit verbundene Kontamination ihrer Charge tunlichst vermeiden möchten. Einer der entscheidenden Faktoren stellt hierbei das Reinigungsverhalten von Oberflächen und das hiermit verbundene Anhaftverhalten von Partikeln dar.

BOLZ INTEC, langjähriger Produzent von Behältern und Sonderkonstruktionen aus Chrom-Nickelstählen, hat sich genau diese Fragen gestellt und die Eigenschaften von Oberflächen in mehrjähriger Forschungsarbeit in Kooperation mit der Hochschule Konstanz untersucht. Hierbei wurde neben dem üblichen Rauheitsprofil von Oberflächen, welches derzeit als Hauptmerkmal bei der Beschreibung von Oberflächenqualität verwendet wird, ein Augenmerk auf weitere Faktoren wie z.B. deren finale Oberflächenenergie in Betracht gezogen und genauer untersucht.

Stand der Technik ist die derzeitige Beurteilung der Oberflächen mit zerstörungsfreien Prüfungen, wie der Rautiefenmessung in Verbindung mit einer optischen Prüfung. Doch gibt es neben diesen, weitere Kriterien, welche nicht außer Acht gelassen werden sollten. Unter anderem wäre hierbei die Art und Weise, wie die Oberfläche veredelt wird zu betrachten. So wurde herausgefunden, dass unterschiedliche Schleifmethoden in der Endbeurteilung der Oberfläche unterschiedliche Anhaftverhalten aufweisen, obwohl der Ra-Wert beider Oberflächen derselbe ist. Das bedeutet, daß die Art und Weise, wie das Material abgetragen wird, hier eine wichtige Rolle spielt. Als Versuch wurde entgegen dem üblichen manuellen Schleifen, der Behälter mit einem automatisiertem Schleifprozess über einen langen Zeitraum geschliffen. Dieser feine Abtrag über einen längeren Zeitraum hatte eine geringere Anhaftung und somit eine bessere Reinigung zur Folge. Dieser wurde im weiteren Verlauf der Untersuchung als finale Oberflächenenergie bezeichnet.

Die aus der Forschungskooperation mit der Hochschule Konstanz gewonnenen Erkenntnisse hat sich BOLZ INTEC zu nutzen gemacht und ein Verfahren entwickelt, bei welchem der geringe und konstante Abtrag der Edelstahloberfläche über einen langen Zeitraum, teilautomatisiert erreicht wird. Das Verfahren wird als Optimized Grind Finishing bzw. OGF-Verfahren bezeichnet. Der Abtrag im Behälter wird mit geometrisch unbestimmten Schleifkörpern, welche sich im Inneren des Behälters bewegen, erzielt. Großer Vorteil des OGF-Verfahrens ist, dass die Oberfläche neben ihrer herausragenden Qualität, reproduzierbar ist. Das Ergebnis ist unabhängig von unbestimmten Variablen, wie z.B. dem händischen Anpressdruck beim konventionellen Schleifen durch einen Mitarbeiter oder der Qualität der Schleifmittel.

Im Verlauf der Untersuchungen in Kooperation mit der Hochschule Konstanz hat BOLZ INTEC mit dem OGF-Verfahren veredelte Edelstahloberflächen weiter veredelt und einem Elektropolitur-Verfahren unterzogen. Bei diesem werden die Spitzen in der Oberflächenstruktur weiter abgetragen, was neben optischen Vorteilen auch chemische Veränderungen, wie z.B. einen verbesserten Korrosionsschutz durch eine verstärkte Passivschicht mit sich bringt. In der Endbeurteilung der Untersuchung wurde das verbesserte Reinigungsverhalten mithilfe eines Versuchs an Anlehnung an die VDA19.1 (März 2015)/ISO16232 (Dezember 2018) aufgezeigt. Das OGF-Verfahren verringert die Restschmutzanhaftung in Behältern drastisch und bietet somit dem Betreiber den Mehrwert, dass das Risiko einer Kontamination zweier Chargen deutlich reduziert wird.

BOLZ INTEC hat mit Hilfe der Forschung eine Oberfläche generiert, welche sowohl in deren Rauheitsprofil, als auch in der optischen Beurteilung wiederholgenau zu erzeugen ist. Zusätzlich weist diese Oberfläche Vorteile gegenüber dem Vergleichsmodell in der Reinigung auf. Gerade für kritische, sehr wertvolle oder sehr feine Partikel kann dieser Mehrwert entscheidend sein. Beispielhaft wären hierfür Branchen wie die Nanotechnologie, die Bio- bzw. Pharmatechnologie oder alle weiteren, bei denen die Chargenreinheit und die Vermeidung von Kontaminationen ein ausschlagender Punkt in der Produktion darstellt.

Sie haben Fragen oder suchen Beratung?

Buchen Sie einfach ein 30-minütiges Erstgespräch über Calendly mit uns.